Project Overview

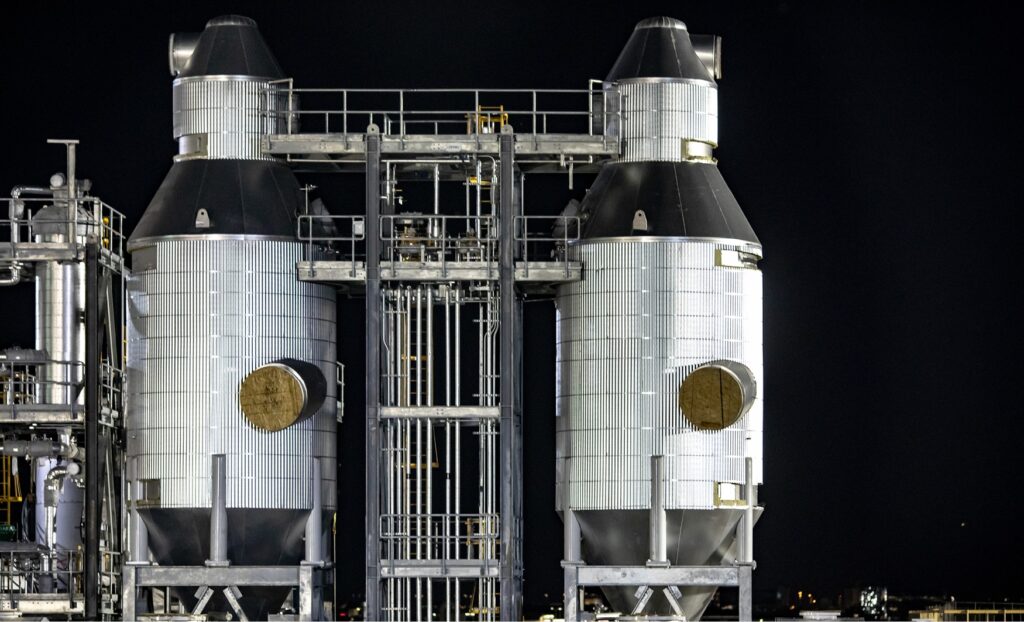

Reyez Construction built a new 12 MGD wastewater treatment and reclaim facility to treat industrial wastewater (IWW) for reuse for a large semiconductor manufacturer with zero liquid discharge onsite. The facility utilizes multiple treatment processes including chemical quenching of the IWW influent stream, biological nutrient removal (BNR), membrane bioreactor (MBR), biosolids dewatering treatment by screw presses, Hp reverse osmosis (HpRO) system, ion exchange system, concentrator and crystallizers, dewatering salt centrifuges, and multiple chemical systems to assist in the treatment processes.

The team took over the project from another design-build team following completion of the preliminary design. The project was significantly over budget and behind schedule, risking impacts to the client’s ongoing production. Our team identified the client’s project goals and the issues with the original design. The project’s aggressive 21-month schedule required several creative solutions, which included phased permitting and early procurement of long-lead equipment, as well as opening multiple work fronts concurrently to meet critical-path demands. Our team’s disciplined project controls systems allowed us to effectively manage the schedule.